The owner, Entertainment Gaming Asia – jointly owned by James Packer and Stanley Ho – had decided in 2013 to transfer the company’s most lucrative division, making casino chips, to Hong Kong along with three injection moulding machines and two patents.

“They were going to shut down the rest of the business and retrench everybody,” Mr Turcarelli told the annual dinner of the Society of Automotive Engineers-Australasia. He had just been elected president of the SAE-A to succeed Adrian Feeney, who had completed the maximum three terms.

“As an afterthought they said ‘but, if you’re interested, you can buy the rest of the business’.”

It was a big decision. Much of Dolphin’s volume was in the form of parts for GM Holden and Toyota, and Mr Turcarelli knew that was a shrinking business. However, Dolphin also produced a range of industrial and medical plastics goods and was already exporting.

“I sat down with my wife and financial advisor and we looked at the numbers and we cut and slashed and burned and thought we might be able to run this business with 26 people,” he said.

“Today we have 36 people, we’ve gone from a 12-hour shift to an 18-hour shift and last week Orica announced a major project for a booster shell for explosives in mining. Dolphin Products will be producing the new booster shell and that project will be worth $31 million over 10 years to Dolphin.

“And it will guarantee the future of our people,” Mr Turcarelli said. The contract will see Dolphin move to a full three-shift operation.

Dolphin had worked on the project for five years with Orica and the company that will make the boosters, the French defence manufacturer Thales. The boosters will replace imported products.

The contract was won against international bidders and Dolphin will be able to install some major new equipment thanks to a grant from the Automotive Diversification Scheme.

Mr Turcarelli said Dolphin had been busy in other areas, developing new products that are made in the company’s own clean room and that pass stringent hygiene tests laid down by the Therapeutic Goods Administration. It has also developed a new production processes that will transform the long-established way in which injection moulding is done.

“The catch cry for Dolphin products for 70 years has been ‘innovation, always’, and I firmly believe innovation is the answer to Australia’s manufacturing issues. We can innovate our way out of it.”

One area where Dolphin has made great progress is in the way it has combined 3D printing into the process for making the tools used in injection moulding machines, especially when it comes to the production of prototype parts.

Adrian Feeney SAE-E President (left) and Mario Turcarelli

The process is known as TruPrint and Dolphin has cut down the lead time from 14 weeks to four weeks, and as little as 10 days for some products.

“Instead of making the whole tool, we just make an insert that goes into the tool,” he said.

“Instead of having to machine a steel block, we send a CAD file to our 3D printer and we make the insert that goes into the tool. And we can make 50 to 100 high-quality prototype parts that can be tested.”

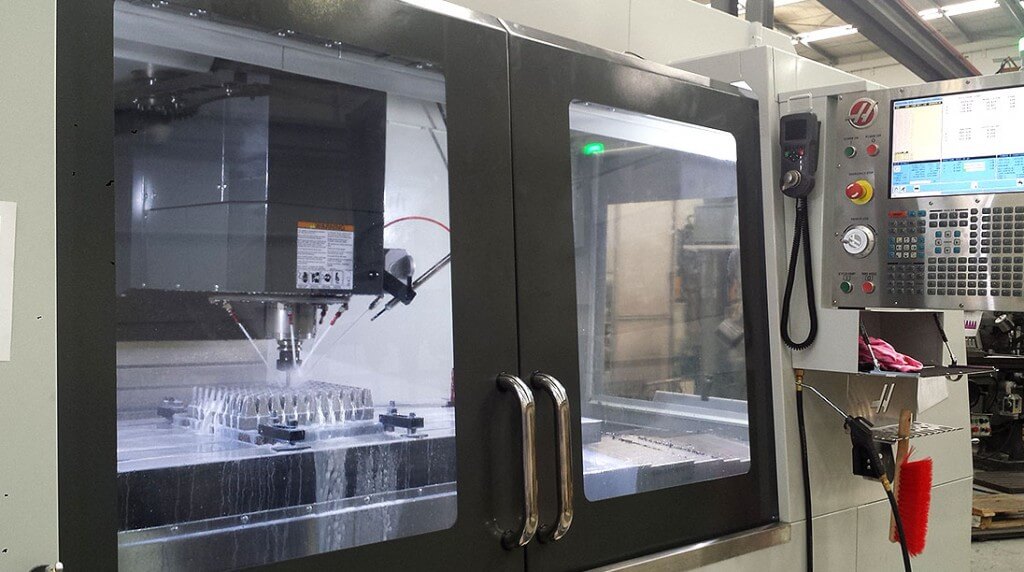

Then one of the company’s key engineers, who came to Australia with the Sauber Formula One team, suggested they use the company’s computer numerically controlled (CNC) cutting machines to make the inserts from aluminium, which would allow the production of 10,000 to 20,000 parts.

If even more parts were needed, the insert could be made from steel, the traditional metal for high-volume production of injection-moulded parts.

“We have actually found a solution to make high-quality parts with very low-cost tooling and, as a result, we have won 17 new customers in the last 12 months and everyone is beating a path to our door because we have innovated injection moulding,” Mr Turcarelli said.

“If you want quick service, you have to do it through us in Australia. And that has made us competitive against imported competition.”

In fact, Mr Turcarelli said Dolphin is exporting to countries that are more famous for exporting to Australia.

“One of the big things about Dolphin is our ability to export worldwide, into some of the most competitive countries: India, Chile, China, Thailand,” he said.

“Half of what we make at Heidelberg is exported because we’ve got really high-tech machines, a lot of automation and we keep our labour costs under control through that automation.”

Mr Turcarelli said the progress made by Dolphin in the past three years made him realise that he got the best part of the deal when he bought the remains of Dolphin from Entertainment Gaming Asia.

“They split the business and took the casino chips. They took three machines and two patents, but one day I realised they had left the most important part of the business.

“They left the people, the people with the skills, the people who developed the casino chips in the first place, and the people who continue to innovate.

“We’ve got the heart of the business and they just took very little, actually. And I paid very little for what was left over, so I got a fantastic deal because I got a really talented and well-skilled team that is continuing to innovate, create new products and push Dolphin Products forward.”

By Ian Porter

Read More: Related articles

Read More: Related articles