The Monash team’s northern hemisphere summer campaign will see it compete against Europe’s best teams at Silverstone in England, the Red Bull Ring in Austria and the Hockenheimring in Germany in July and August.

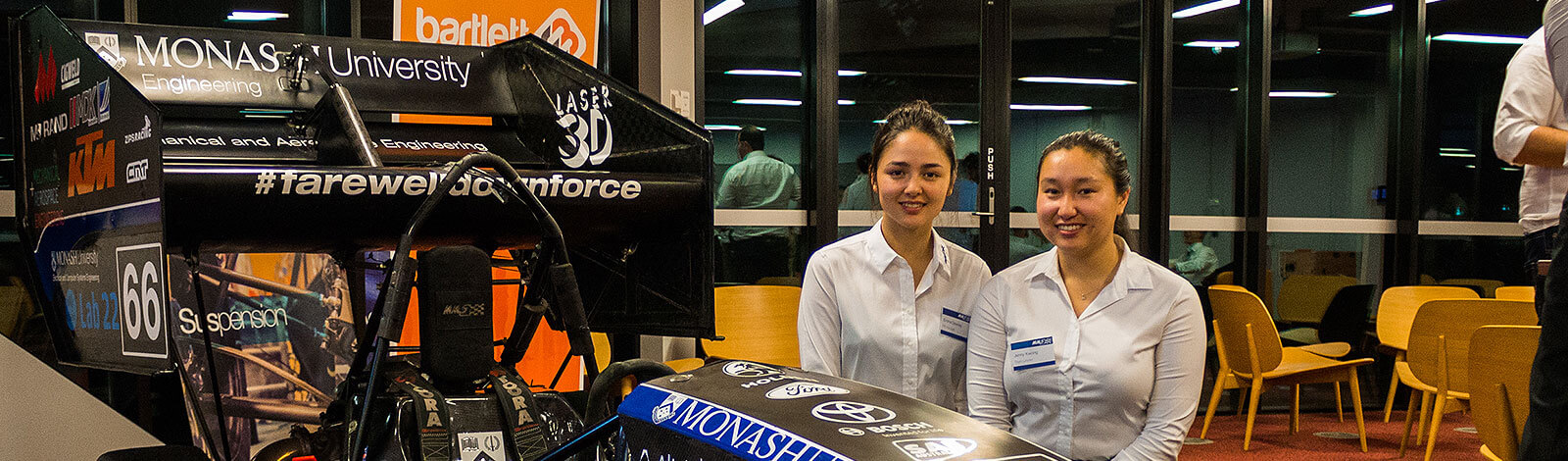

The team outlined its European campaign at a farewell ceremony at the university’s Clayton campus and also revealed plans to build a second car so that it could also enter the electric vehicle part of the Formula-SAE competition starting in 2017.

The team won its seventh straight Australian title at Calder in December, but has not been resting on its laurels, according to team leader Jenny Kwong.

“This will be out most ambitious year ever, with four competitions on two continents,” she said. “Since January, we have been developing M15R, the car we will take to Europe.

“Whilst this has been happening, M16 has also been in development. This is the car that will compete in the 2016 Australian competition later this year.”

The team is currently ranked third in the world standings, which include 511 teams from 45 countries. It ranked second in the world in 2012 and 2013 but slipped to seventh in 2014 before bouncing back. The competition is called Formula Student in Europe.

The M15R has been thoroughly revised since it won at Calder in December and will have more power when it competes in Europe and a new set of carbon-fibre rims mounted on aluminium wheel centres or “spiders”.

“Following our success at the 2015 Australian competition … we identified three key areas where we could improve before starting the European campaign,” chief engineer Sam Hughes said at the launch.

“They were the engine and powertrain package, the suspension and the tuning and setup of the car.”

The team has added an intercooler from Harrop Engineering and a boost controller which together have lifted the power of the turbocharged single-cylinder KTM engine from 46kW to 52kW. The extra power has increased cooling requirements, so the team has added a second radiator to mirror the original one on the right hand side of the body.

In addition, the team has developed its own pneumatic clutch actuator which gives faster shift times and a quicker launch from zero.

Mr Hughes said the team has also improved what is perhaps the car’s most advanced system, its interconnected hydraulic suspension system, which not only connects each front wheel with the other and each rear wheel with the other but also the front wheels with the rear wheels.

The system allows each wheel to move independently of the other three, while stiffening the suspension for the outside wheels in a particular corner.

The team used a damper dynamometer and on-track testing to hone the system since December and Mr Hughes said he believes there has been a solid gain in lap times.

The Monash team has also constructed its first full carbon-fibre rims after using rims that were half metal and half composite 2014. They will be mounted on aluminium spiders.

“In terms of the outboard suspension, it’s the first time we have ever run on full carbon rims and we have also redesigned our wheel centres. This has resulted in a 70g weight reduction on rotational and unsprung mass on every corner,” Mr Hughes said.

The downside is that the carbon-fibre wheels are more expensive than spun aluminium wheels and that increases the cost of the car in that part of the event that measures how expensive it would be to make the car.

“We had to weigh up what we wanted, a lighter car or to save some money,” Ms Kwong said.

“That’s one of the trade-offs you have to make in Formula SAE. It keeps the competition fair because, while a team might be able to use advanced engineering and production techniques, that will increase the cost of its car.

“So it allows a team with a simpler design to gain some points back and it also challenges those teams that have expensive cars to justify that cost within the event and why this is a good manufacturing decision.

“The whole premise of the competition is that you are a mock company that is building a prototype vehicle for mass production. In the cost event you are pretending that you are going to make 3000 vehicles.”

The team has expanded from about 60 to more than 100 people this year following the decision to make an electric car as well as the successful internal combustion model.

The electric powertrain manager for the electric car project, Jack Robinson, said Monash Motorsport had formed a partnership with the Chisholm TAFE college, which has been working on electric go-karts, among other projects.

“This has enabled us to further our knowledge on how the technology works and how to integrate it into an electric vehicle and the effects it has on the vehicle’s dynamics and performance.”

The EV will have Emrax brushless motors, one on each wheel and a UniTek motor inverter. Mr Robinson said the team was examining batteries made by Korean company Energy Innovation Group (EiG), which are claimed to have the best cell efficiencies and power per unit of battery weight.

The team will compete at Silverstone from July 14 to 18, at Red Bull Ring from August 1 to 4 and at Hockenheim from August 9 to 14.

There will be 140 cars competing at Silverstone, 42 in Austria and 110 in Germany.

By Ian Porter

Click to enlarge

Read More: Related articles

Read More: Related articles