An Australian research company is testing the concept of capturing the energy from a pulse jet engine as a range extender for electric vehicles.

Some readers will know of the pulse-jet engine as a novel power unit for remote-controlled planes while older readers may remember it as powering Nazi Germany’s V1 rocket used to bomb Britain in the Second World War.

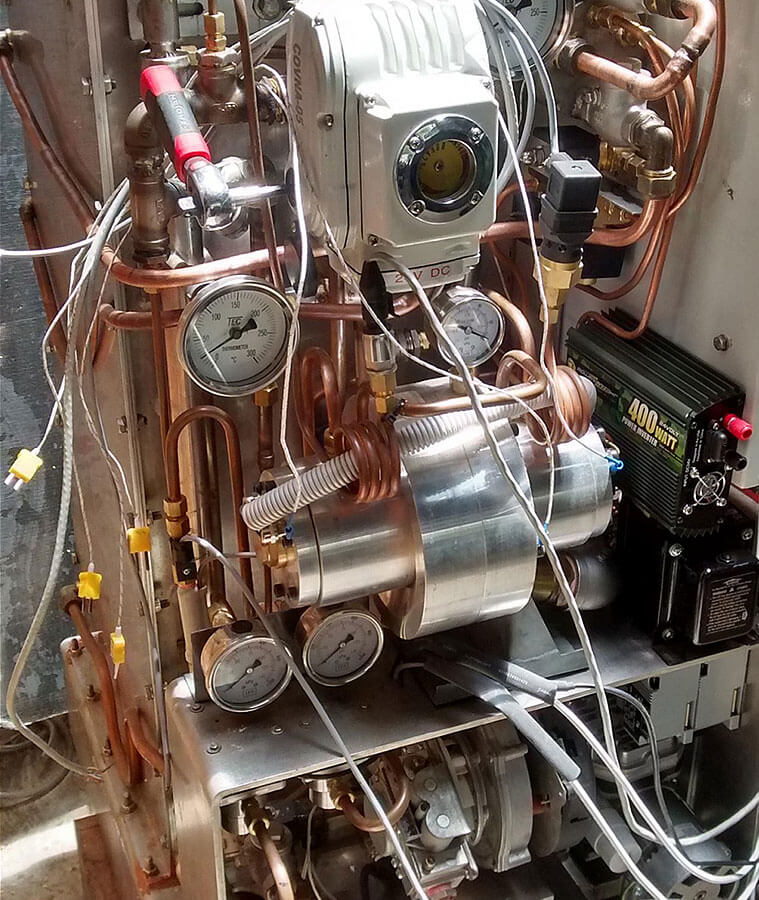

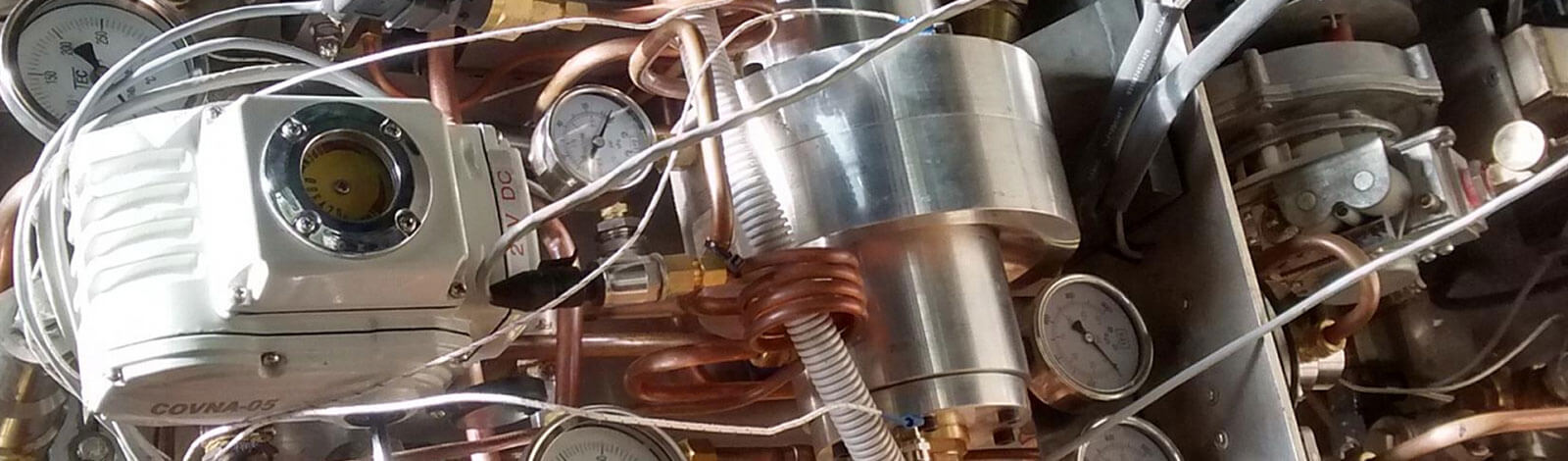

The only moving part is the air intake valve or shutter that operates automatically.

The pulse jet engine is powerful and able to operate on a variety of fuels, including liquefied petroleum gas (LPG) that is used in the prototypes built by Gold Coast research and development company Delafield Pty Ltd with cooperation from Dockland Science Park Pty Ltd.

This company is run by engineer and inventor John Martin who also heads LPG-Liquid-Inject Ltd which was responsible for the injected LPG system used by the Ford Falcon.

“The pulse combustion is well developed and that it is a matter of developing applications of the technology,” he said.

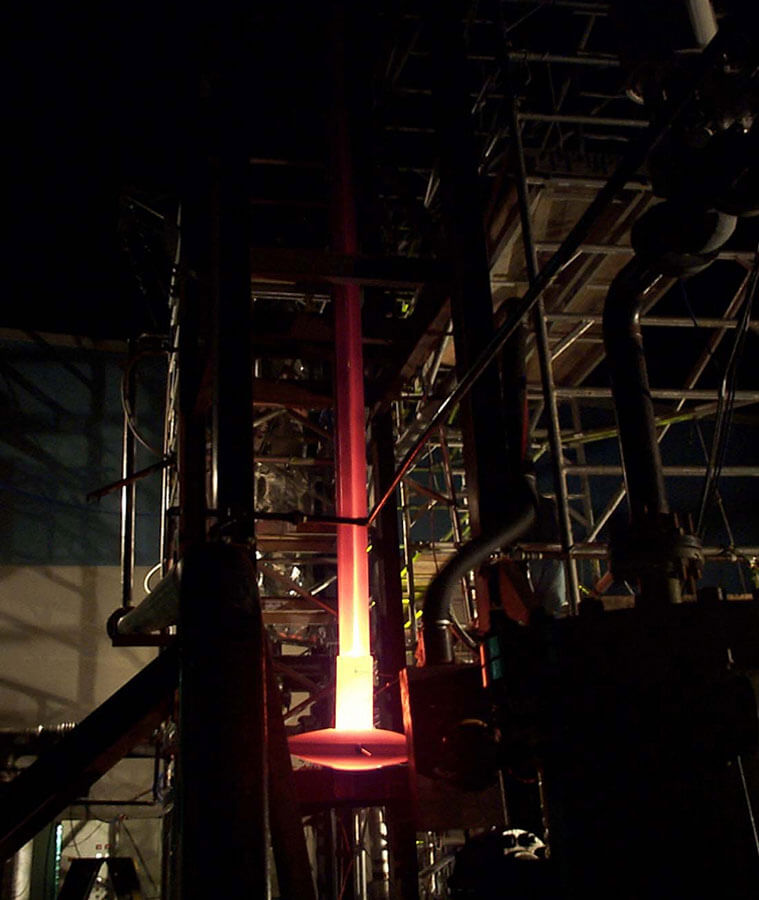

“It can be applied as a stationary or range-extender generator, but because of its high thermal efficiency, can also be used as a steam generator.”

Mr Martin said he had two gas-fuelled pulse engines on trial. Both the 250kW and 500kW engines are designed as powerplants for stationary generators or for use as range-extender generators for vehicles up to heavy-duty trucks and earth-moving equipment.

Mr Martin said a 500kW pulse combustion unit operating on compressed natural gas (CNG) was in operation in Queensland and a 250kW version fuelled by LPG is used on the Darling Downs.

“The units are modular so we can easily combine two 500kW units to give a 1000kW unit,” he said.

“The 500kW unit compares favourably in box size and weight to a 500kW diesel.

“But it is more fuel efficient and has no toxic nitrous emissions, only carbon-dioxide and water.”

Mr Martin said he sees potential for the manufacture of the units in Australia for export.

He said he was keen to see a 15kW unit built and attached to the Australian Axiflux modular electric motor/generator to create a compact power unit for an electric car.

“That hybrid drive system can be sold worldwide for inclusion in small vehicles,” he said.

“Other highly efficient generators, or electric motors are currently available, such as the ‘Yasa’ from Oxford University.”

Mr Martin said a pulse combustion unit emits only carbon dioxide and water and has no nitrous or sulphur oxides. It is also claimed to be 60 per cent thermally efficient.

“That compares to (around) 33 per cent for most motor vehicles,” Mr Martin said. “Our LPG-fuelled engines – such as the Ford Falcon – can achieve 40 per cent efficiency.”

The engine will run on a variety of fuels but Mr Martin believes LPG better suits applications in Australia.

“In our view, the best fuel is LPG and it is an area in which we have considerable expertise as Ford used our liquid LPG system in their LPG-fuelled vehicles,” he said.

“LPG is also readily available in Australia and so doesn’t need to be imported, plus it is a clean fuel in comparison to petrol and diesel.”

He said pulse engines will operate on most fuels including coal gas, biodiesel, diesel, and even strained fish and chip oil, and that biodiesel was a good choice for remote areas or farming communities because it will burn without needing to be refined.

Mr Martin is now seeking funding for the project to build further engines, particularly the 15kW unit to act as a vehicle range extender.

By Neil Dowling

Read More: Related articles

Read More: Related articles