In single automotive plant terms, it is only eclipsed by the disposal of the Mitsubishi Motors Australia Ltd facilities in South Australia in 2008 that fetched about $15 million.

Already the Toyota Motor Corporation Australia (TMCA) disposal – initially by sale of equipment excess to ongoing car production and then from October, by auction of manufacturing machinery in the first quarter of 2018 – has brought potential buyers from India, Europe and the US to inspect the equipment.

GraysOnline has been appointed by TMCA to manage the sale of plant and equipment from its manufacturing plant in Altona, Victoria, in conjunction with global specialist machinery and equipment disposal specialist Hilco Industrial.

Hilco, in 2015, managed the sale of Ford’s Belgium body production plant and has completed about 50 automotive factory closures in the past 12 years.

GraysOnline automotive manufacturing national manager Lloyd Gourel said that “in terms of sheer size and value and a recognised brand, the MMAL disposal has been the biggest”.

“Now we have 10 disposals with most being parts suppliers to Ford, Toyota and Holden, either individually or together,” it said.

“In the majority of cases, we are selling 100 per cent of the assets. There are some cases where some equipment and machinery will be retained by the company concerned, usually because it would be transferred to one of its other plants in another country.

Toyota Altona North

“In Toyota’s case, the Altona manufacturing plant is being retained for use as the company’s new head office and R&D centre.”

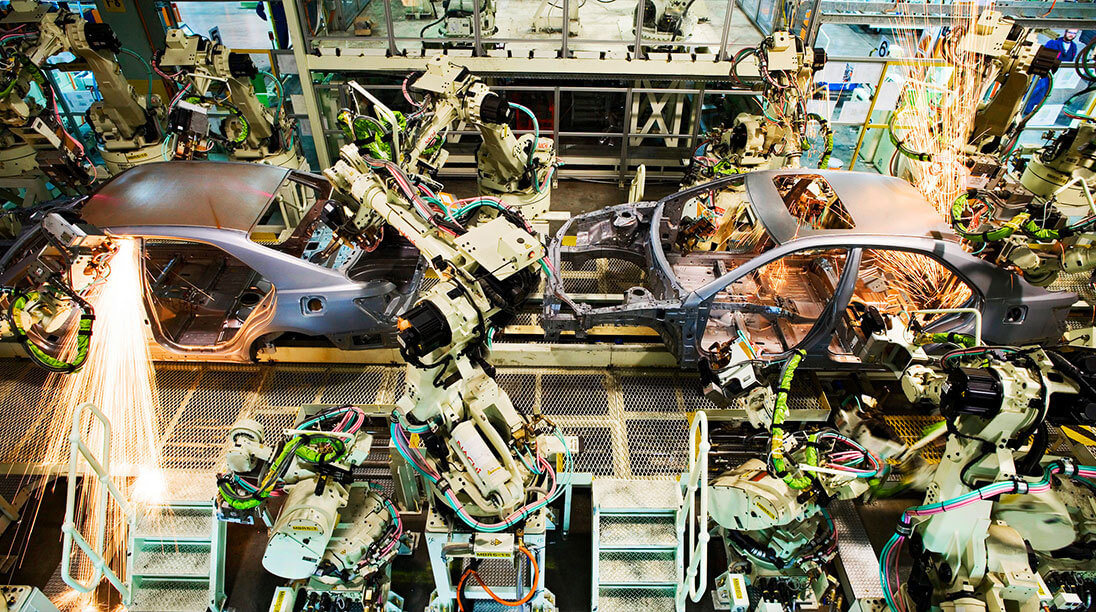

The Toyota assets coming up on the block include the paint shop, assembly shop, weld shop, resin shop and engine shop, together with smaller services such as the plant for the buildings.

GraysOnline is also handling the disposal of equipment for South Australian-based Ai Automotive which makes metal pressings for the car industry and for whitegoods; for Britax Childcare (baby seats and restraints); and Chassis Brakes International of Bentleigh East in Victoria which made brakes and steering assemblies.

Futuris Automotive Interiors, which supplies Holden, has a private treaty sale of its equipment at Adelaide through US-based Liquidity Services Inc and Maynard Industries.

The Futuris equipment includes headliner and seat assembly machinery and trim fabricators.

Both Liquidity Services and Maynards are acting for Holden in the sale of over 8000 assets including presses, plastic injection moulders, CNC machines, robots and instrument panel assembly lines.

Liquidity Services Australia managing director Jeff Morter told GoAutoNews Premium that of that item total, about 80 per cent would be sold through an online auction.

As of June 2017, he reports intense interest in the Holden assets from Australia and over 18 countries.

Toyota Manufacturing Auction

“The auction we held on the 19th of this month had a lot of interest from the US and India,” he said.

“Private treaty negotiations have seen interest or bidding from a large range countries including China, India, Italy, Ukraine, Poland and Yemen.”

In terms of size, Mr Morter said it was too early to gauge the Holden sale in dollar terms, though it was “in the millions, if not tens of millions” of dollars.

The remaining pieces are being prepared for sale as the manufacturing winds down at the Elizabeth plant in Adelaide on October 20 this year.

The sale and auction by Maynards and Liquidity Services includes the entire car assembly line for right-hand- and left-hand-drive Zeta-platform cars.

The two companies are also selling the assets of Futuris Automotive which is comprised of mainly machinery and equipment for making automotive interiors.

Toyota’s sale will be by private treaty with remaining unsold items sent to auction, Mr Gourel said.

“Toyota’s equipment that is not needed is progressively being sold – and has been from May – and we expect to auction the remainder early next year,” he said.

Toyota Manufacturing Auction

“Toyota may retain some high value assets but the rest will be sold or auctioned.

“It won’t be as big as Mitsubishi, though at this stage it is hard to gauge.

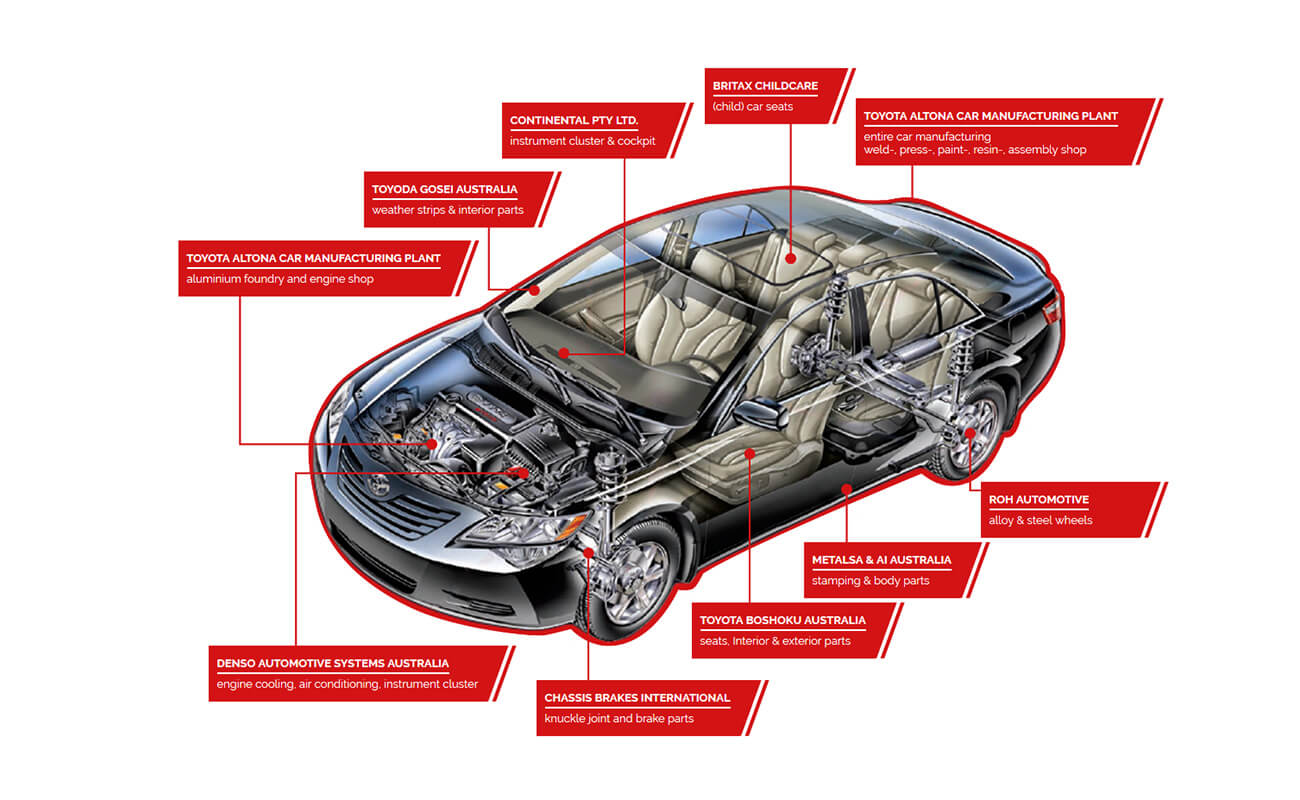

“Toyota’s Altona plant is the only one in the world that does every part of the car manufacturing. So on one site, it does everything from making the engine to driving a complete car out the other end.

“For that reason, there’s a broad spectrum of machinery that’s being offered. In addition, there is equipment from suppliers like Toyota Boshoku that makes car seats, and Toyoda Gosei for rubber parts, and ROH Automotive for alloy wheels.

“We have had dozens of inquiries from overseas and are regularly facilitating inspections for overseas buyers. One recent Indian company planning to send representatives for inspections has 38 plants in India for the automotive industry.

“The company, Maruti, was also interested in the Metalsa equipment that stamps body panels from sheet metal.”

Mr Gourel said the stamping equipment was not limited to car panels but could be used for any metal stamping operations including furniture and parts for any type of machinery or equipment.

Though the interest has been strong, Mr Gourel said potential buyers had to weigh up the cost of moving the equipment.

“The large machinery has to be decommissioned,” he said.

“Then buyers will have to do their homework. The price of the machinery has to be weighed up against the price of moving it. It has to be packaged and shipped, in most cases a long way from Australia, and this can cost hundreds of thousands of dollars.”

Holden’s Elizabeth plant, which began construction in May 1958 and finalised its body line in 1962, was the subject to a bid in 2016 by Belgian entrepreneur Guido Dumarey.

He wanted to buy the entire plant but eventually agreed with Holden that making volume cars in Australia was not viable.

By Neil Dowling

Read More: Related articles

Read More: Related articles