The machine, called Qure, has been sold for $1.5 million and installed at the Korea Institute of Science and Technology (KIST) which is a major player in South Korea’s automotive industry development.

Quickstep would not confirm that it would make parts specifically for Hyundai or Kia, noting only that KIST would be the conduit for potential manufacturing contracts.

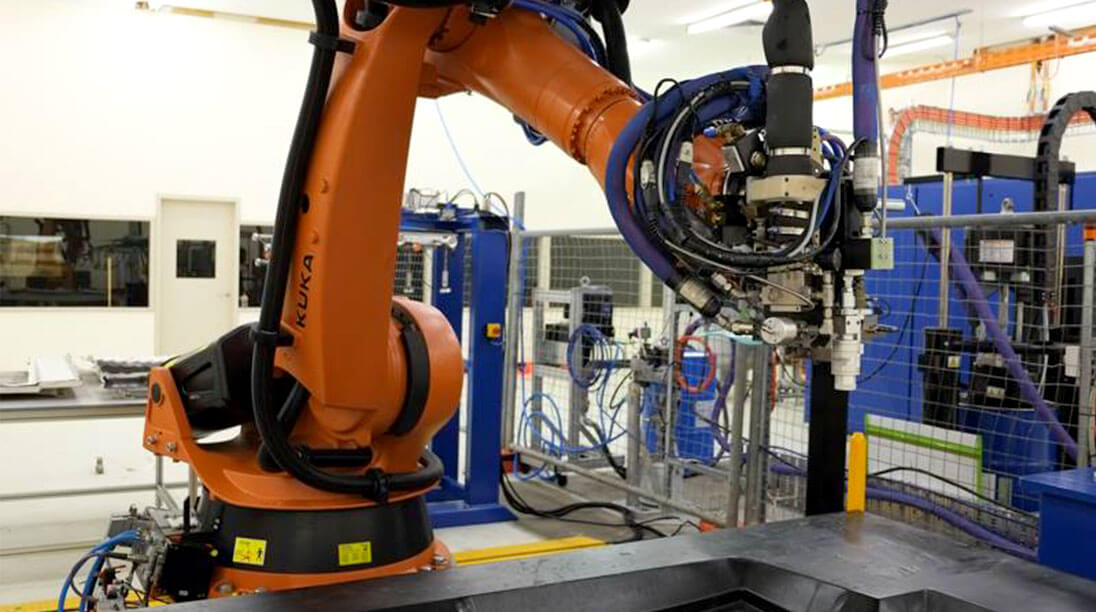

But it is understood that the Qure technology – which has advantages of traditional carbon-fibre manufacture including using fluids to cure the process instead of autoclaves – would be first seen on Genesis models.

Quickstep technology is already used to make carbon-fibre composite roofs for some Audi models – notably the A1 hatchback – and more products are expected to be added.

It has received a $1.45 million grant from the Australian government from the Competitive Research Centre Project to develop lightweight carbon-fibre composite automotive seats that the company said could lead to global contracts.

Concurrently, it appointed Ross Mahon as executive general manager of its “new technology” division. Mr Mahon was most recently the COO Asia Pacific of global automotive parts maker – and particularly seat manufacturer – Futuris Automotive.

Assistant minister for Industry, Innovation and Science, Craig Laundy (centre), with Quickstep Holdings Ltd’s former managing director and CEO David Marino (right) and Advanced Manufacturing Growth Centre managing director Dr Jens Goennemann (centre left).

In February this year, Quickstep was also awarded a $250,000 grant from the Australian independent group, the Advanced Manufacturing Growth Centre (AMCG), to develop a carbon-fibre composite fender “for the European automotive market”.

Neither Quickstep nor the AMCG would detail who the fender would be used for though it was presumed it was an extension of the Audi contract.

AMCG said the grant would allow Quickstep and Deakin University’s Carbon Nexus Research Centre to collaborate on materials development and validation.

The company is also finalising completion of 10 sets of body panels made of carbon-fibre composite for the Hawkei military vehicle. The sets are made up of 190 individual components and will be tested once production is finalised.

Quickstep is also continuing with its main business of manufacturing aerospace components, delivering 310 parts – predominantly wing sections – for the Joint Strike Fighter jet project and for the Lockheed Martin C-130J Hercules.

Quickstep is gaining popularity because though carbon-fibre composites are increasingly used in the automotive industry, it is expensive to produce with much of the cost associated with the high labour and the autoclave – or industrial oven – necessary in traditional construction to cure the resins.

In its recent financial report, it said it had $115 million of forward orders for its technology.

By Neil Dowling

Read More: Related articles

Read More: Related articles