As of last Friday there were 13 car ships moored off the Port Kembla car shipping terminal near Wollongong in NSW and just two car carriers in the port itself, many of them containing large numbers of vehicles ordered by buyers in full expectation that they would receive the full asset write-off when they placed their deposits.

A back of the envelope calculation, assuming they were full of cars, would mean that roughly 40,000 cars, SUVs, utes, vans and trucks are stranded off Port Kembla alone.

As reported by Pitcher Partners in last week’s GoAutoNews Premium, the Labor government will bring the instant asset write-off rules to a close as of June 30 leaving only weeks now for business owners to get their cars delivered to qualify for the tax benefit.

The report has dealers scrambling for cars to deliver in time for the deadline.

But the chances are that only a few of the vehicles stranded at sea off Port Kembla and at other car shipping terminals around the country will be delivered to business buyers in time for the June 30 cut-off date.

The apparent unfairness of buyers missing out of the tax break, when they had ordered their vehicles in a timely way, has prompted the Australian Automotive Dealer Association chief executive James Voortman to call for special consideration.

He has suggested that buyers who placed their orders before the end of the first quarter this year should qualify for the write-off no matter how long it takes to get the cars cleared from the docks.

He told GoAutoNews Premium: “There is no doubt that the significant delays at our ports will result in businesses not being able to take delivery of a new vehicle in time to make use of the temporary full expensing measures which are expiring on July 1.

“The delays at the ports are being caused by Australia’s strict biosecurity laws, which the automotive industry fully supports.

“But it is not fair on customers who ordered new cars, trucks or vans with a view to improving the productivity of their business to be told that they will not qualify for the investment incentive due to no fault of their own.

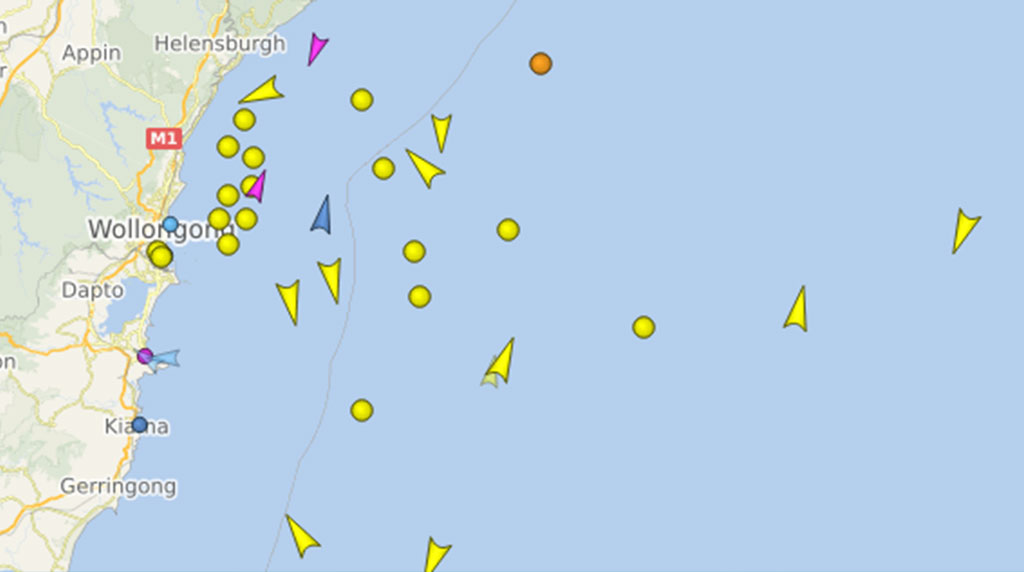

The scene off Port Kembla as of last Friday. Thirteen car ships share the waters with bulk carriers. Just two car carriers are in port.

Source: vesselfinder.com

“I do fear that customers may cancel orders if they realise that they no longer qualify for the accelerated depreciation. That obviously will not be good for dealers, but will also not be good for those tradies and small businesses which were seeking to boost the productivity of their businesses.

“We would urge the Government to exercise some leniency which takes into account the unprecedented delays in the automotive industry. Perhaps allowing vehicles ordered prior to the first quarter of 2023,” he said.

Meanwhile, according to shipping industry sources, the job of actually getting cars off ships and into dealerships seems to be hindered by the inability of our ports to deal with the volume in terms of adequate staff and infrastructure surrounding Australia’s stringent biosecurity rules.

A lot of the problem is apparently caused by the countries that ship cars to Australia which have not properly addressed our tough regulations

As of May 19, a flotilla of 13 car carrying ships was anchored off one the country’s main vehicle off-loading facilities at Port Kembla with a further two, the Artemus Leader and the Tonsberg, in the port itself.

The car carriers offshore were the Toronto, Viking Passama, Frontier Ace, Hoegh Trapper, Hoegh Oslo, Hoegh Berlin, Aphrodite Leader, Ivory Arrow, Dugong Ace, Dream Beauty, Eridanus Leader, Elegant Ace and the Paganella.

Each of these car ships carry between 2000 and 4000 vehicles although some carry up to 8000 vehicles. When averaged out, this means tens of thousands of vehicles are waiting to clear just this one port.

Extrapolated nationally to include Sydney, Fremantle, Adelaide, Melbourne and Brisbane, that number is significantly bigger.

Insiders also say that some car ships have been diverted to the NSW port from other states due to processing problems.

There have also been some reports that car ships have been returned to the source country to have cars cleaned to the standards required in Australia and then shipped back here for immediate off-loading. Still other ships are said to be sailing to Indonesia where contractors are cleaning the cars for return to Australia.

A spokesperson for a car importer affected by the port congestion told GoAutoNews Premium that the problem has existed ever since the demise of the local car manufacturing industry because, from that point on, every vehicle sold in Australia must come across the docks – more than a million a year.

The spokesperson said that neither private companies nor the government have been prepared to invest enough in upgraded ports and associated facilities to cope with the volume increase.

“I understand Port Kembla can handle two car ships with its existing staffing and infrastructure but, if you add in biosecurity requirements, to have every vehicle thoroughly inspected and washed if necessary before dispatch, you run into a serious logistical problem.

“I’ve been told Port Kembla only has about half a dozen wash bays.”

GoAutoNews Premium has been told that Australian Government officials from the Department of Agriculture, Fisheries and Forestry have been visiting countries that export cars to Australia to explain details of our Biosecurity Act as it affects imported motor vehicles.

Manufacturers are being encouraged to ensure their vehicles are clean before being shipped while car carriers are reported to be diverting vessels to third countries for the cleaning of vehicles before they arrive in Australia.

Delegations have previously visited countries such as Thailand to ensure vehicles comply when they are loaded aboard vessels.

According to a report in the Sydney Morning Herald, cars coming from China caused the most issues in 2022, with 10,900 of the 148,200 vehicles imported from that country referred for cleaning for contamination. This was followed by Thailand, Spain and Japan.

Argentina had the greatest percentage of contaminated vehicles, with 2900 of the 4500 cars imported being flagged for cleaning.

Some manufacturers say their imports, which they have cleaned and wrapped before shipping, are being contaminated during the voyage by other dirty vehicles on board. Figures show up to 88 per cent of imported vehicles are affected by biological contaminants.

As reported in GoAutoNews last month, Port of Melbourne corporate relations manager Simon Watson said the delays ultimately stem from an increased number of improperly stored vehicles at overseas ports prior to departure for Australia.

Mr Watson said that vehicles are being parked in substandard conditions for longer than usual periods caused by delays surrounding microprocessor and other parts shortages.

That was resulting in contamination from what is known as biosecurity risk material (BRM), or soil, plant and insect matter that poses an unacceptable risk to Australia’s fragile agriculture, forestry and fisheries industries.

“We are seeing strong demand for new motor vehicles into Port of Melbourne, and with this an increase in BRM arriving on these vehicles. This includes soil, plant debris, seeds and live insects which are not present in Australia,” Mr Watson said.

“Such exotic pests and diseases if established pose a real threat to our food production and agriculture industries, therefore biosecurity risk management through the Port of Melbourne remains a key focus.

“We understand that a proportion of the increase in BRM is due to seasonality, but there has also been a significant increase in BRM due to new vehicles being stored for long periods in paddocks and parking areas due to global supply chain issues.

“This has left vehicles exposed to the elements, where they inadvertently collect BRM while held at port of loading.”

In a statement, the Department of Agriculture Fisheries and Forestry said: “Biosecurity risk material must be removed from contaminated vehicles prior to being released. This cleaning is carried out by commercial companies.

“Current delays to the delivery of new vehicles are a direct result of the capacity of the commercial companies to manage the surge in contaminated vehicles arriving at the border.

“There are no delays associated with Department of Agriculture, Fisheries and Forestry responsibilities in this process.

“Biosecurity officers undertake surveillance to check for biosecurity risk material on vehicles arriving Australia and confirm the effectiveness of the cleaning undertaken by commercial companies prior to the release of vehicles.

“There are no resourcing shortages with biosecurity officers undertaking the surveillance processes, nor are there any delays associated with inspections by biosecurity officers.

The department is working with the Federal Chamber of Automotive Industries (FCAI) and its members to encourage and assist them to implement offshore cleaning measures.

“Some already have effective measures in place, which reduces biosecurity risk and import delays on arrival.

“The department strongly encourages the FCAI to work with its members to establish offshore cleaning measures where they do not exist.

By Peter Barnwell and John Mellor

Read More: Related articles

Read More: Related articles